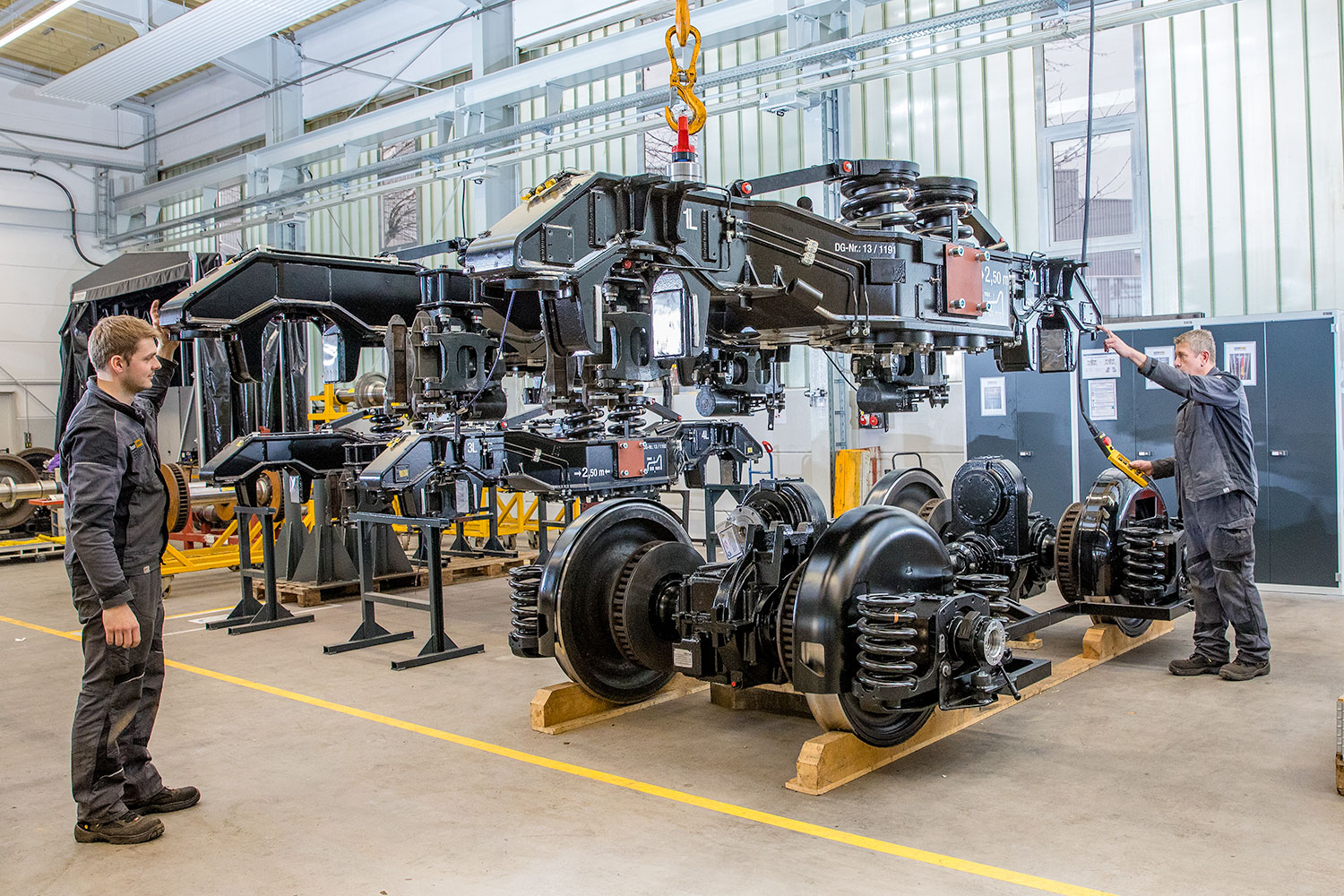

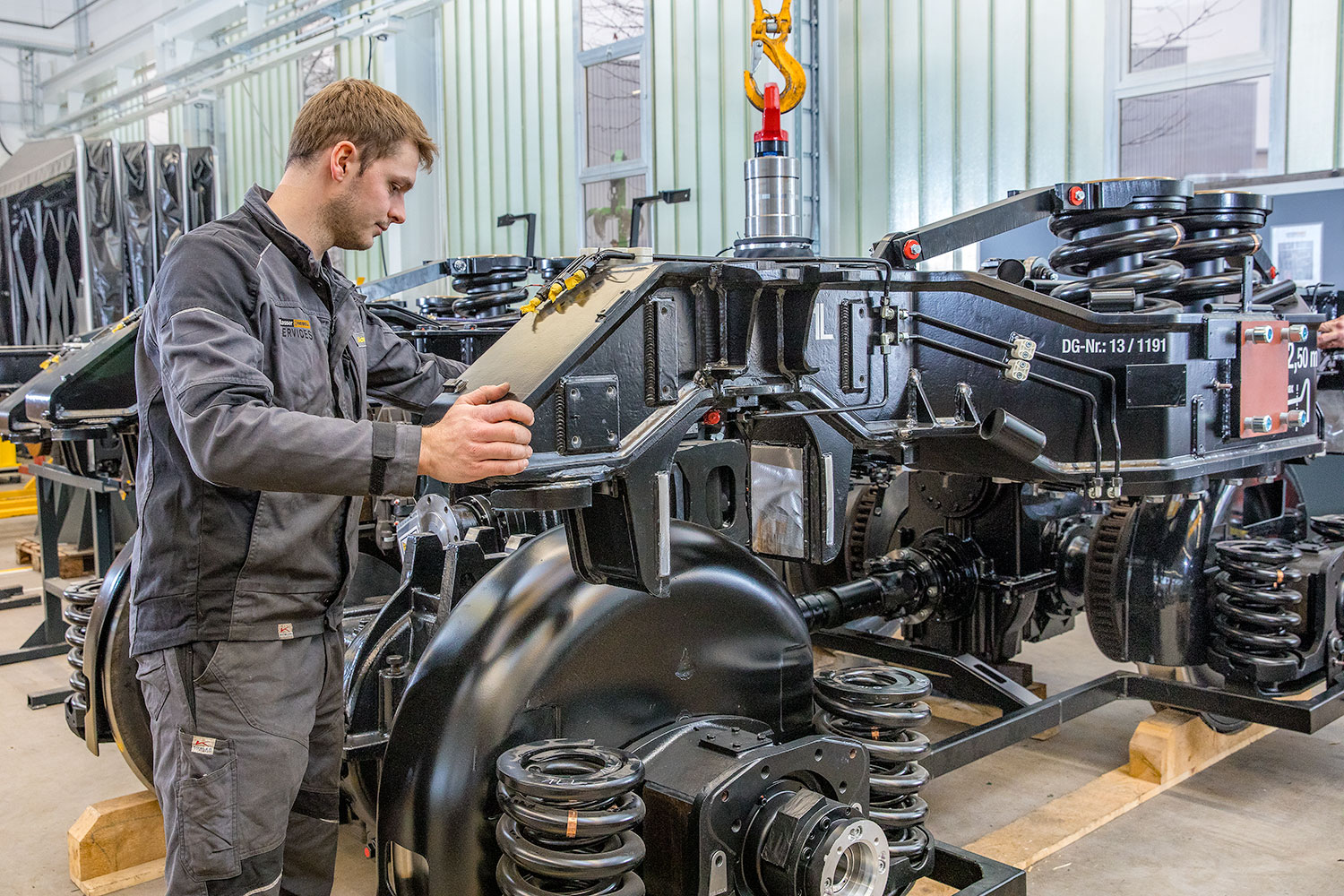

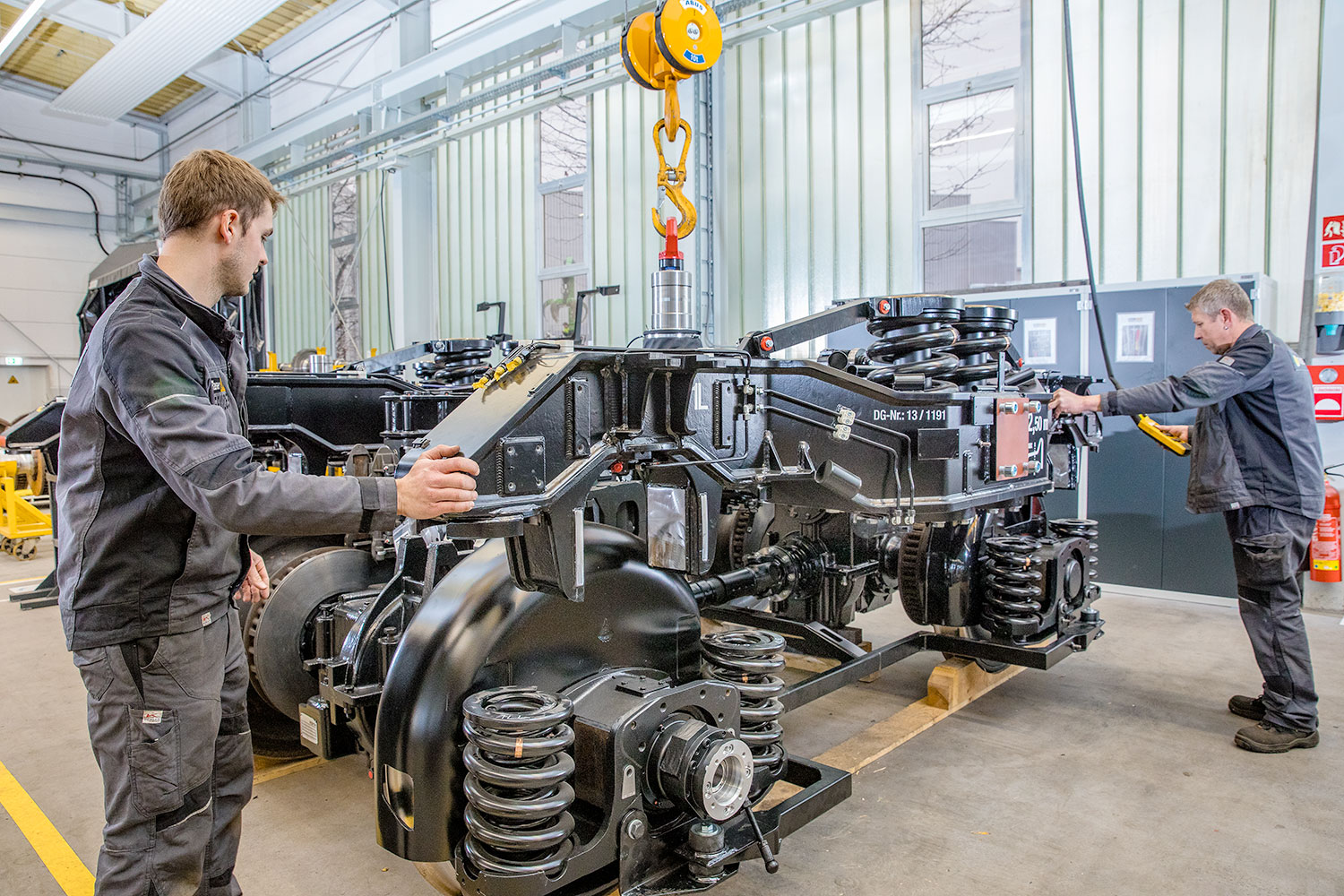

WHEELSET | BOGIE SERVICE

The wheel-rail contact is highly relevant to safety. For the reconditioning of wheelsets and bogies, PRS therefore makes use of the great depth of added value in its own plant as well as our Europe-wide certified service competence. We act quickly and deliver reliably so that your vehicle is ready for use again as planned.

Revision

PRS carries out the legally required revisions for wheelsets and bogies (e.g. EBO §32) of all known brands. You receive standard-compliant quality and maximum planning reliability:

Wheelset press

Your benefit:

Technical parameters

| Year of manufacture | 2015 |

| Wheel diameter | 500-1,000 mm |

| Track gauge | 700-1,668 mm |

| Axle length | 1,140-2,500 mm |

| Max. wheelset weight | 2,500 kg |

| In accordance with applicable regulations | DIN EN 13260, etc. |

Bogie test rig

Your benefit:

Technical parameters

| Year of manufacture | 2022 |

| Bogies | 2-axle, powered and idler bogies |

| Track gauge | 800 mm – 1,676 mm |

| Wheel diameter | 500 – 1,300 mm |

| Bogie length | ≤ 5,300 mm |

| Bogie height | max. 2,100 mm |

| Bogie width | ≤ 3,300 mm |

| Bogie weight | ≤ 20,000 kg |

| Wheelbase 2-axle travelling gears | 1,300 – 3,300 mm |